Dr. List engineering has developed a variety of solutions for customers in different areas of academic and industrial research. These projects are specific and subject to non-disclosure agreements.

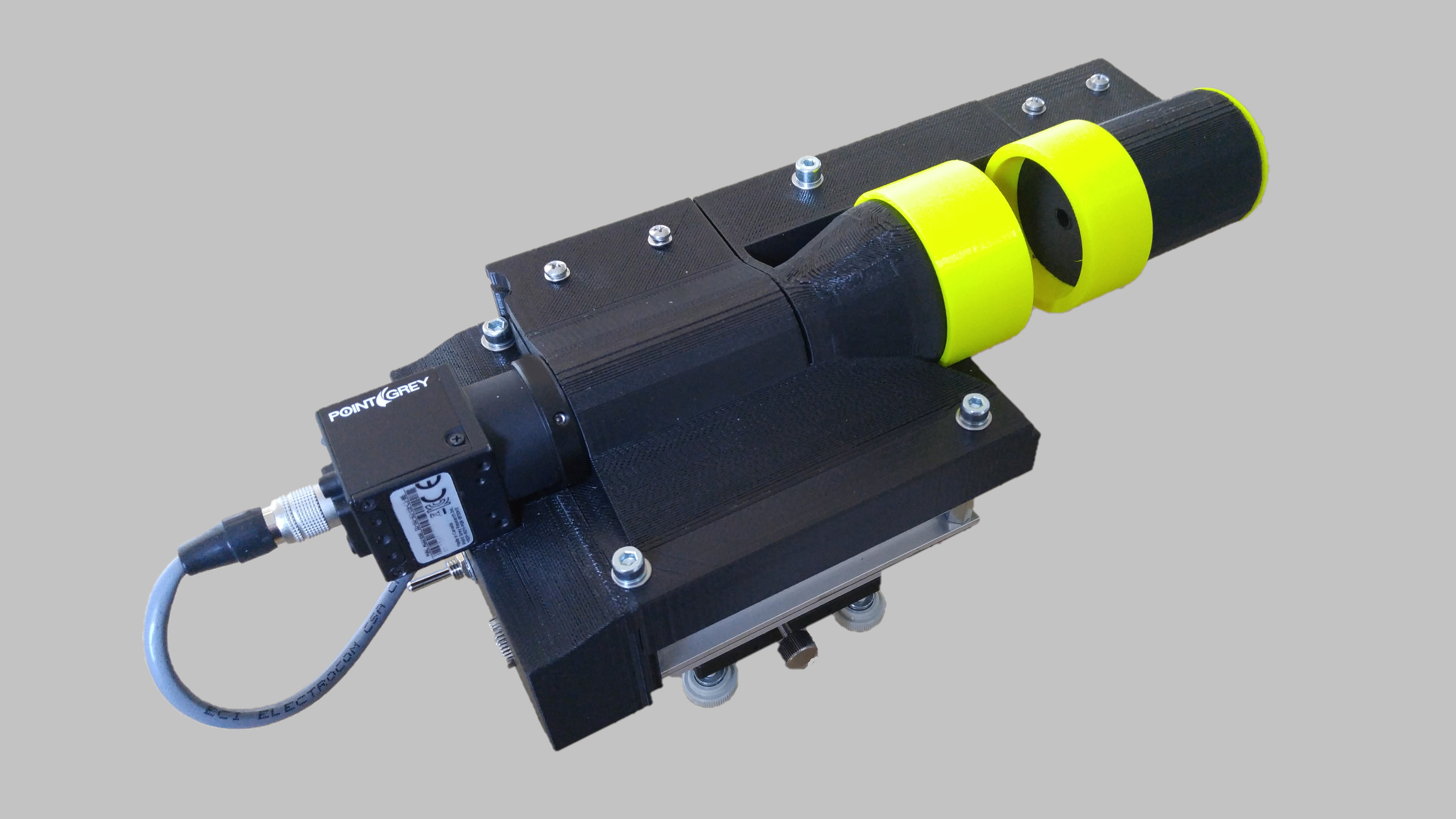

Commercially available is the inline inspection system for the real-time monitoring of the manufacturing of thin diamond wire. The first system was named ISWIN: inline saw-wire inspection. The system is made for the continuous inspection of the whole length of the saw wire.

The first model of ISWIN was able to measure the wire parameters at speeds up to 1m/s without a loss in precision. Tests were carried out at up to 20m/s wire speed with very good results.

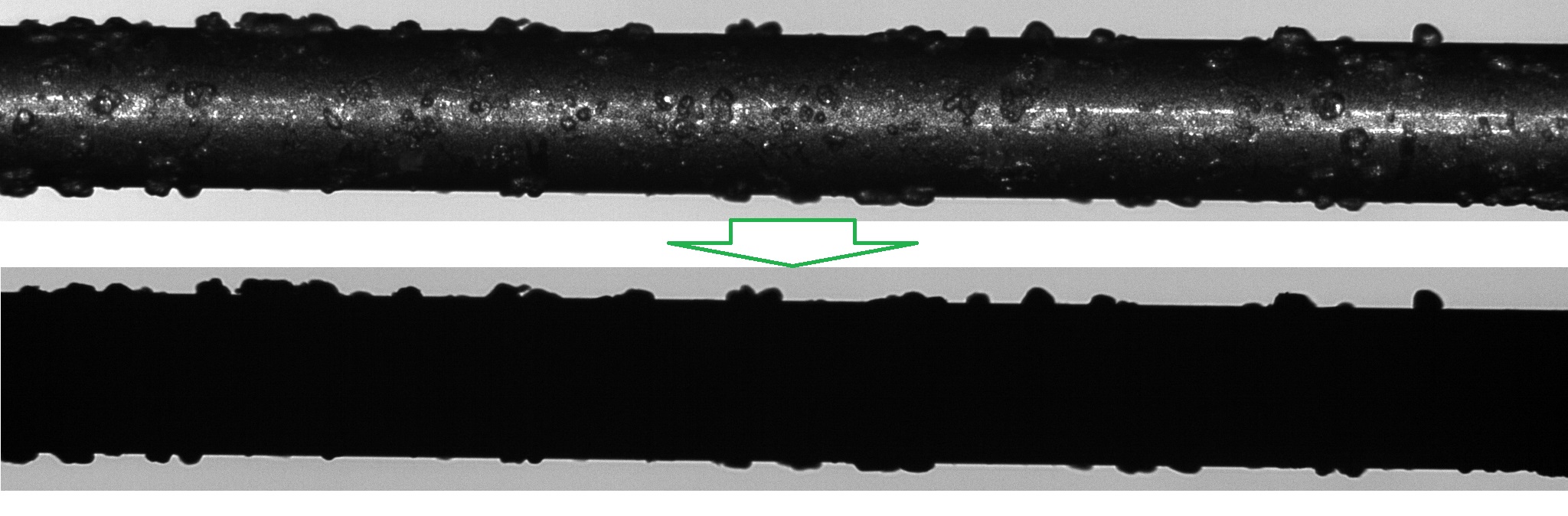

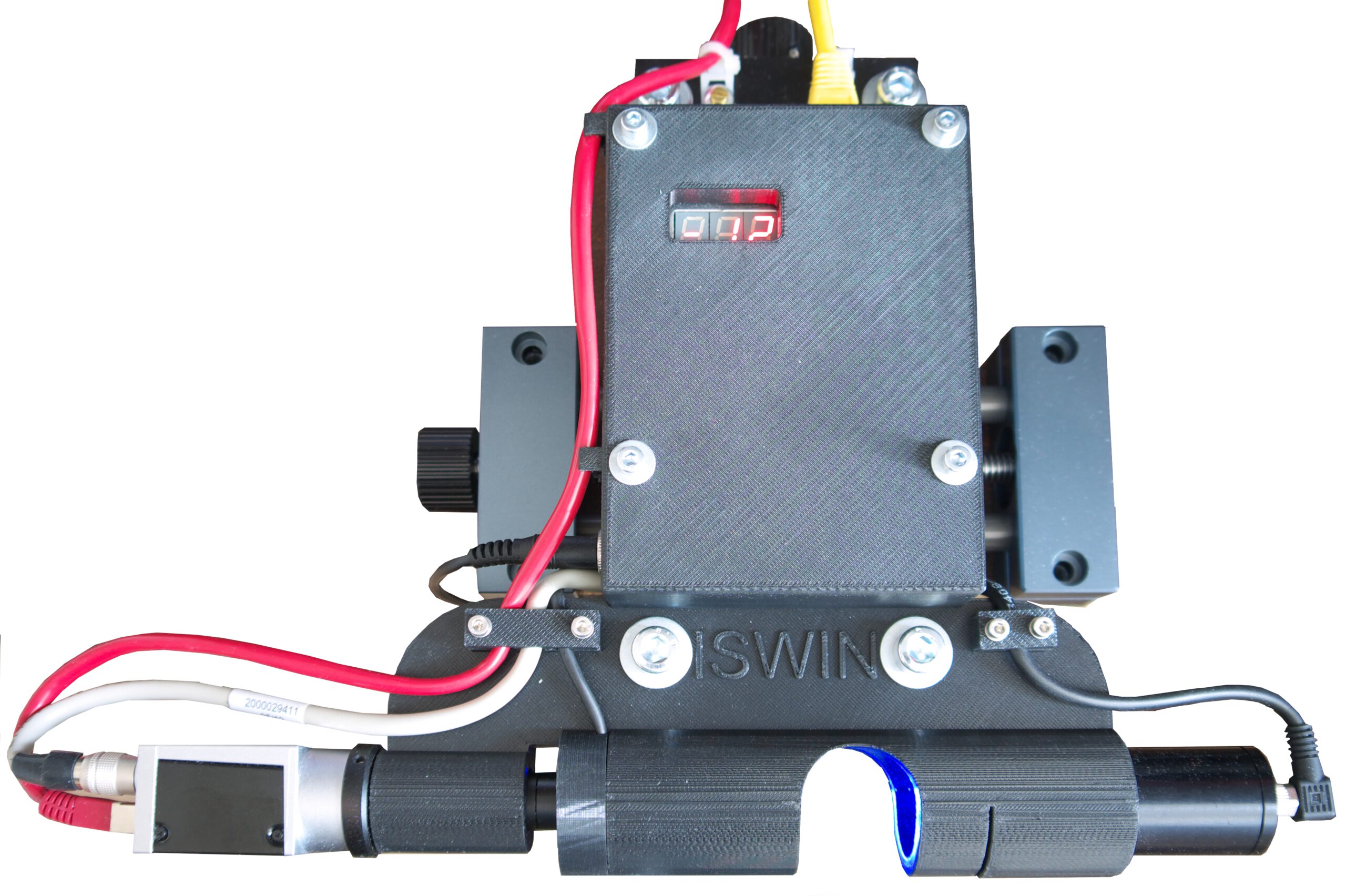

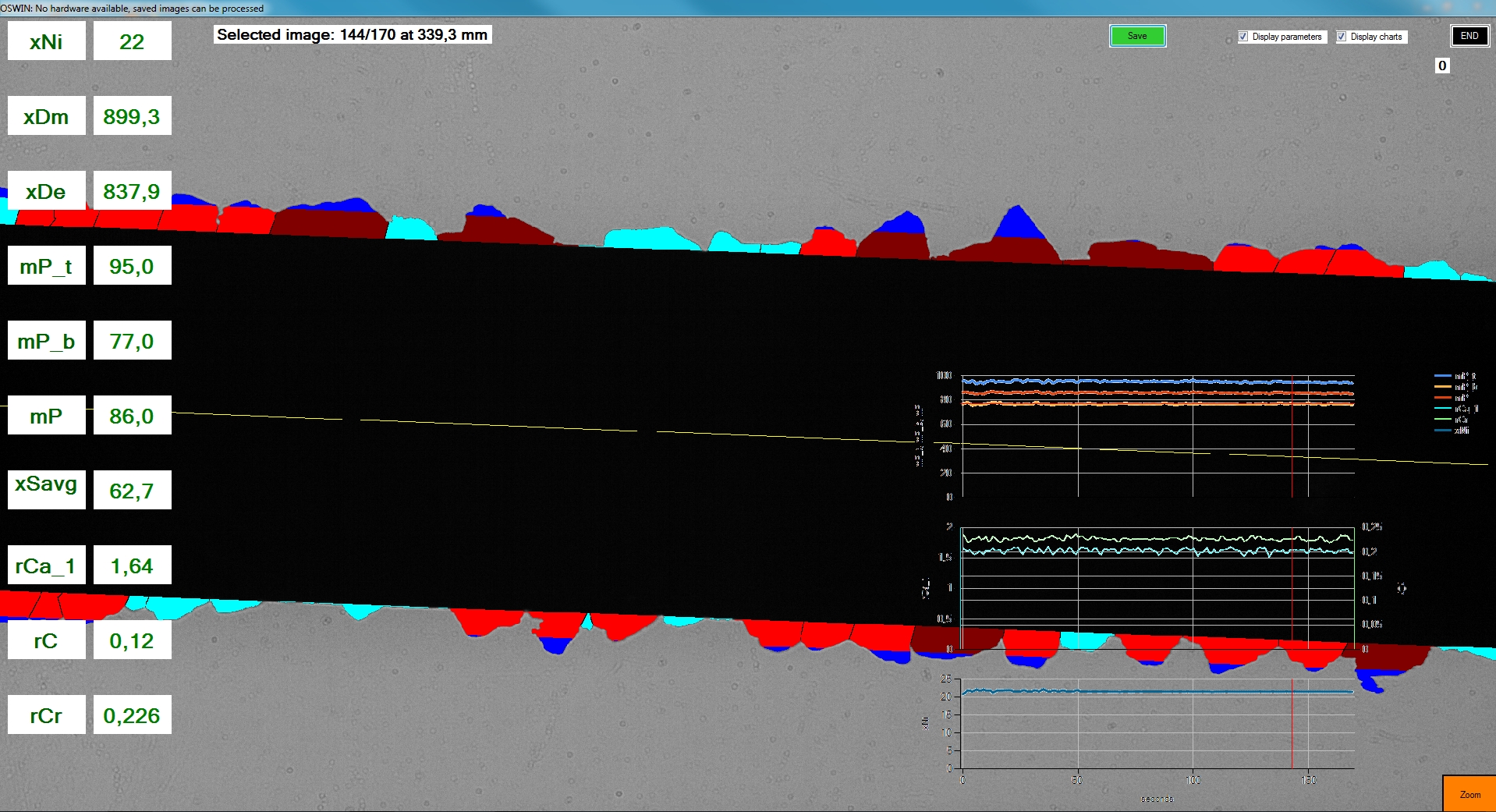

The second generation, ISWIN2, combines the perfomance of precise measurement at high speeds with the ability to capture surface images at high speeds. The extended software triggers alarms at programmable limit violations and stores images of the wire at these conditions.

ISWIN2 is a useful QC tool for both the manufacturer and the user of thin diamond wire.